MULTIHEAD WEIGHERS

Atlas packaging machines supplies a very extensive range of high-quality and durable multihead weighers and linear weighers for the food and non-food industry.

The multihead weigher is the most ideal machine for accurately filling bulk solids at a high speed with a very constant weight. Think of products such as: snacks, candy, animal feed, nuts, grains, cherry tomatoes, coffee, tea, parts, coconut powder, washing powders, sugar, rice, seeds, lettuce, frozen products, popcorn, carrots, biscuits, onions, radishes, chips , puffed snacks, etc….

Multihead weigher; high speed and very accurate

Depending on the desired speed, the weight to be dosed and the product to be filled, Atlas packaging machines can put together the ideal multihead weigher for you. We can supply multihead weighers with very small buckets (100 ml) for extremely high accuracies (up to 0.1g), to multihead weighers with 5 liter buckets for the larger weights. Our 10, 14, 20 and 24 head multihead weighers are characterized by high reliability, weighing speed and sublime accuracy. We use the latest generation microprocessor control with canbus for stable and fast performance. The electronics have a modular structure. Each channel has 1 control unit for the linear feeder, the collecting bucket and the weighing bucket. Very compact and well-arranged design, easy trouble shooting and low maintenance costs. The many variations in designs make our multihead weigher usable for a wide variety of different products and weights.

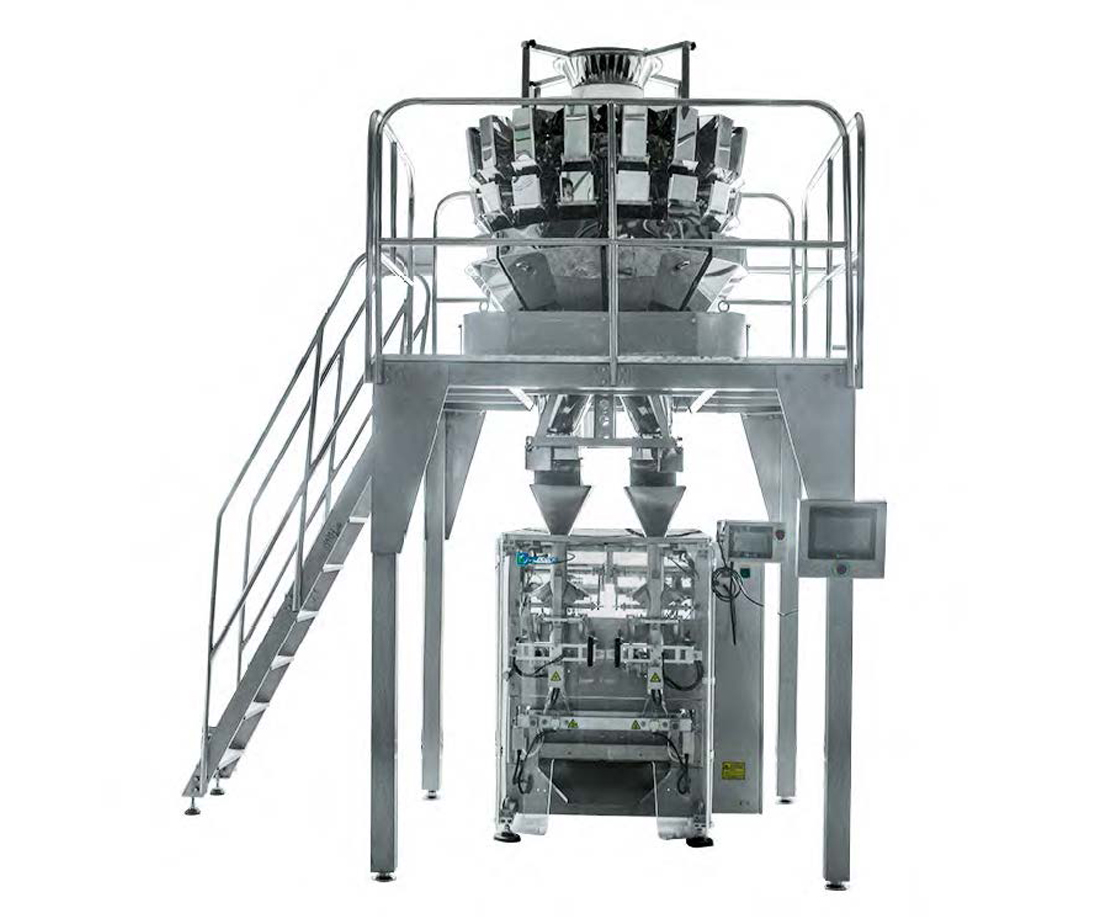

The multihead weigher is often used in combination with. a vertical packaging machine (VFFS), tray sealer, rotary doypack machine etc.

Atlas packaging machines can supply these multihead weighers as a stand-alone, but also as a complete solution. Including the correct FDA-approved feeding system, the custom-made stable stainless steel platform and the correct packaging machine. The big advantage for you is that you have one contact person.

With our more than 20 years of experience, we can offer you a more than suitable solution, which is favorable in terms of price/quality ratio.

We would also like to be that partner for the future for you, who can advise and relieve you.

Principle multihead weigher

A multihead weigher consists of a central cone, a number of vibrating chutes, a number of storage bins and a number of weighing bins. With most multihead weighers, these numbers will be between 10 and 24. The higher the number, the faster and more accurate the weigher is. The central cone, which is located on top of the multihead weigher, is supplied with product via an elevator belt, for example. The amount of product on the cone is detected by sensors. Depending on the amount of product, the supply will start or stop automatically. The cone will distribute the product evenly over the vibrating channels via the rotating or vibrating movement. These vibrating channels move the product to the storage bins. An intelligent control system ensures that the ideal amount of product reaches the hopper. These storage bins then deposit the portion in the lower weighing bin. This only if it is empty or requires more product. The accurate load cells determine the weight in the weigh bucket. Each weighing bucket contains approximately a quarter of the set weight and the weigher calculates the best combination that is within the limits of the target weight. These selected bins are opened and come together via the central discharge funnel before being dumped into the packaging machine.

Version and options

Our multihead weigher is completely made of stainless steel 304 (stainless steel 316 is an option) and easy to clean because all trays, gutters and chutes can be disassembled and assembled without tools. We have specially designed weighers for:

- cold wet areas (IP 66 version with heating and dehumidifier in the control cabinet

- seeds/light expensive products. Weigher with 0.1 liter buckets equipped with very high-quality load cells. Weights from 0.5 g with an accuracy to 0.01 g

- bean sprouts long noodle products.

- very fine heavy granules.

- Fragile products such as biscuits/candy.

Due to the different available volumes of weighing buckets (0.1, 0.5, 0.8L, 1.6L, 2.5L and 5L), a suitable solution can be offered for every weight and volume.

Video’s

Opties

NEED ADVICE?

Also take a look at

other solutions

Switch language?

Atlas Packaging Machines

Europe